Digitalisation and technological innovation offer the pathway to the future of energy supplies and achieving carbon net zero. So, when we talk about digitalisation in our industry, we mean:

- Replacing manual or physical tasks with digital solutions

- Streamlining work processes by reducing time spent on manual or repetitive work

- Advanced analysis of data – to better understand and utilise the vast and complex data sets that can improve our decision making and performance

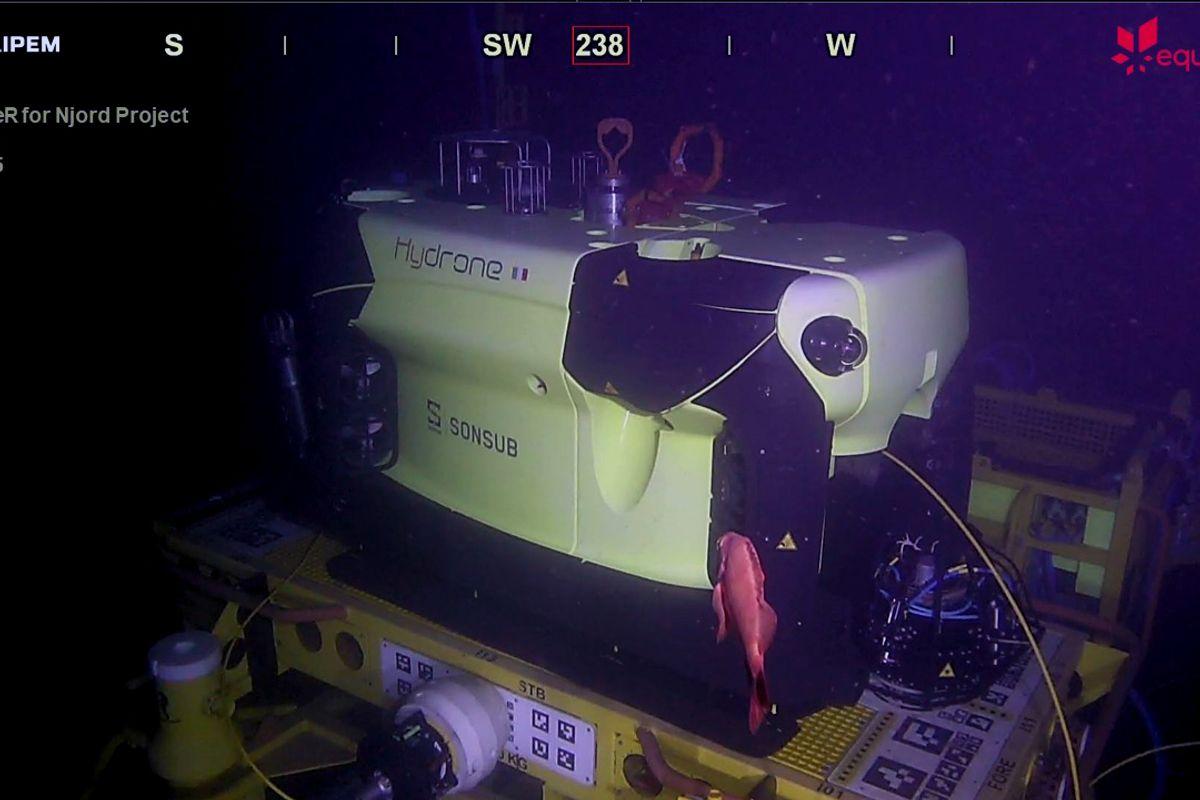

- Robotisation and remote control, improving operational regularity, reducing cost and improving safety by reducing human involvement in dangerous tasks and environments

- The internet and industrial internet of things (IoT, IIoT), big data, predictive and prescriptive analytics and artificial intelligence.