High gas exports and emissions cuts from Hammerfest LNG

(UTC)Last modified

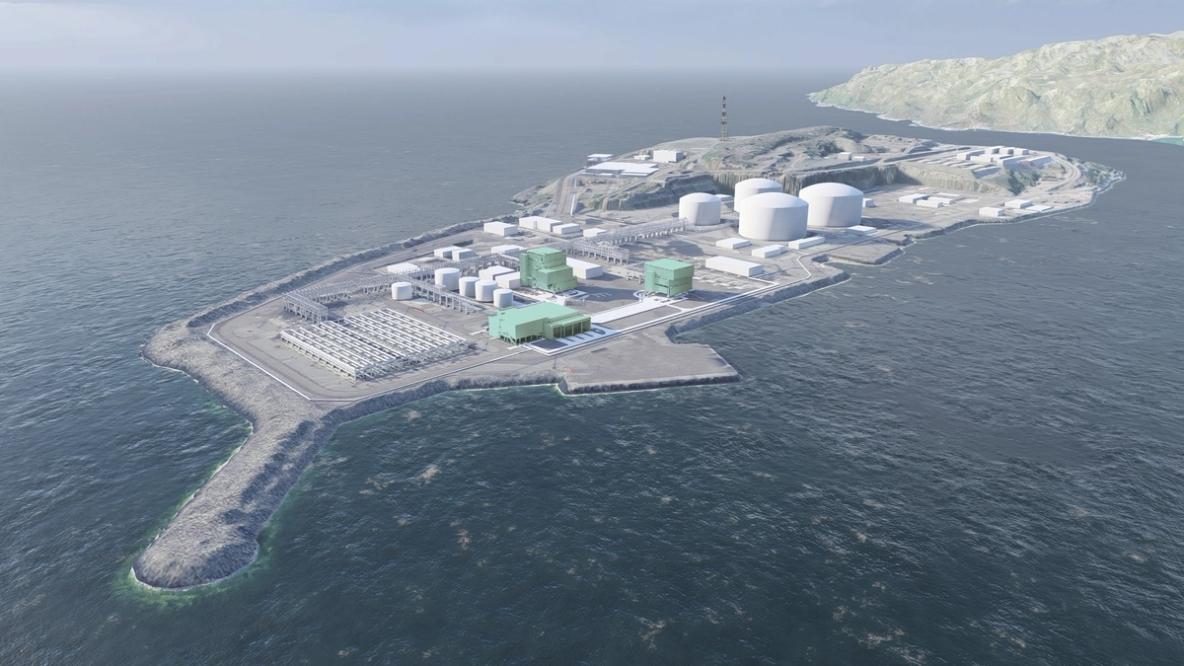

The Hammerfest LNG plant at Melkøya.

(Photo: Ole Jørgen Bratland / Equinor)

The Snøhvit partners will invest NOK 13.2 billion (2022) in upgrading the Hammerfest LNG plant, HLNG, at Melkøya. The project involves gas onshore compression and electrification and will secure the future of HLNG.

Snøhvit Future

- The licence owners of Snøhvit are: Equinor Energy ASA (36.79%), Petoro AS (30.00%), TotalEnergies EP Norge AS (18.40%), Neptune Energy Norge AS (12.00%) and Wintershall Dea Norge AS (2.81%).

- The Snøhvit field lies in the central part of the Hammerfest basin in the southern part of the Barents Sea. The water depth is 310 – 340 metres. Snøhvit was proven in 1984, and the original plan for development and operation (PDO) was approved in 2002.

- Snøhvit was the first field to be developed in the Barents Sea. The field comprises the Snøhvit, Albatross and Askeladd structures.

- Snøhvit Future Project consists of two developments: Snøhvit Onshore Compression and Snøhvit Electrification.

- The development covers: 1) the onshore compressor, transformer station and electric steam boilers on Melkøya, 2) the grid connection including a transforming station at Hyggevatn, and 3) the development of new power capacity from Skaidi to Hammerfest.

- Onshore compression will help maintain sufficient inlet pressure for the LNG plant as the reservoir pressure drops. It will also reduce the risk of accumulation of fluid liquids in the long multiphase pipeline from field to shore. This will give a longer operational window and extend plateau production.

- Electrification of Melkøya will minimise emissions from LNG production, leading to an annual emission reduction of close to 850,000 tonnes of CO2, equivalent to the emissions from 450,000 fossil-fuelled (ICE) cars.

- It will reduce the carbon footprint from LNG production at Melkøya from 3.8 to 0.6 g CO2e/MJ.

- Emissions reductions from HLNG meet the requirements stated in the authorities’ approval of the plan for development and operation of Snøhvit from 2002.

- Onshore compression and conversion to electrical operation of HLNG are scheduled to start in 2028.

Hammerfest LNG

- Hammerfest LNG is Europe’s first large-scale liquefied natural gas (LNG) plant and is located on the island of Melkøya outside Hammerfest.

- Coming on stream in 2007, the plant is a cornerstone in the Finnmark region, employing around 500 people, including apprentices and contractors.

- The plant contributes strongly to value creation and activity through the use of local suppliers and purchase of services.

- HLNG produces 4.65 million tonnes of LNG, 0.34 million tonnes of LPG and 0.73 million tonnes of condensate per year. (LNG = liquefied natural gas, LPG = liquefied petroleum gas).

- Hammerfest LNG produces around 6.5 billion cubic metres per year at normal production, equivalent to the annual gas demand of 6.5 million European homes.

- Recovery and transport to shore are carried out from the Snøhvit, Albatross and Askeladd fields. The gas arrives at the plant via a 143 km pipeline. At the plant, the natural gas is processed and cooled to minus 163 degrees, after which it is stored in dedicated tanks before shipment. All products (LNG, LPG, and condensates) are exported by vessels or vehicles.

About the development solution

- The development project will involve major constructions on the island of Melkøya and on the mainland.

- Three modules will be constructed: a module for a feed gas compressor, a module for electrical steam boilers and a transformer station.

- High voltage cables will connect Melkøya to Hyggevatn substation and the national grid. A tunnel will be constructed to bring the cables from Hyggevatn to Meland. Between Melkøya and Meland, subsea cables will be installed.

- The grid capacity to Hammerfest will increase thanks to the new grid reinforcement planned by Statnett between Hyggevatn and Skaidi.

- For 15 years, one of the world’s most energy-efficient LNG plants has delivered liquefied natural gas to customers all over the world. 350 permanent employees ensure stable and safe operations, and Bodø Science Park has proven that the total ripple effects in North Norway are around 900 full-time equivalents.

- The project will secure important jobs for decades to come, representing a continuation of this major industrial adventure, both in the project phase and the operations phase.