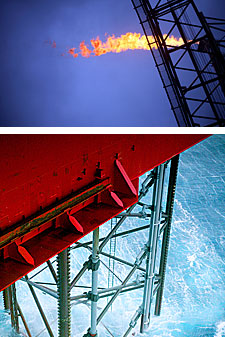

The Volve field has been developed with the world's largest jack-up platform as its mainstay. This gives increased flexibibility and lower costs for a field that is predicted to have a shorter lifespan than other North Sea fields. (Photo: Colin Dobinson)

"Against a background of high oil prices and diminishing production from mature fields, we must be willing to think afresh," said Torvund. "We have strategic focus on maximising returns from the Norwegian Continental Shelf, and we see a trend towards smaller and more marginal fields," he said.

"The classic project for StatoilHydro has been major fields. Volve shows that we are innovative and can be competitive on smaller fields too," said Tore Torvund before travelling out to Volve to undertake the official opening. (Photo: Colin Dobinson)

Torvund, who is executive vice president for Exploration and Production Norway, held a presentation for Norwegian media at StatoilHydro's guest house at Solastranda in Stavanger on Friday morning, before flying out to the official opening on the platform Mærsk Inspirer.

Mærsk Inspirer is the world's largest jackup rig, 103 metres wide and with a maximum drill string length of 9.15 km.

(Photo: Colin Dobinson)

The Volve field represents an important contribution to production targets with its daily production of 56,000 barrels of oil per day. StatoilHydro's share of this production is 30,000 barrels per day.

"Although it's not typically StatoilHydro, Volve represents the diversity in the way we will be operating on the continental shelf according to varying challenges," explains Torvund.

Subcontracted to Mærsk

Part of what's new at Volve is the way in which the entire operation has been assigned to Mærsk Contractors Norway. Mærsk have had responsibility for development, equipment and manning.

"It's as close as you can get to a total procurement and construction contract," said Torvund, while emphasising that StatoilHydro remain in charge of the geology and placement of wells. He praised Mærsk Contractors Norway for their deliveries.

"We have achieved almost 100 percent regularity already, even during the startup phase. That is something that really impresses us," he said, and added that he was happy that Mærsk too, were satisfied. "When you have two parties that are satisfied, you can call it a success," he said.

"We have only praise for Mærsk, who have carried out their responsibilities for development, equipment and manning in an exemplarary fashion," said Torvund in the ceremony conducted on board.

(Photo: Colin Dobinson)

Torvund and managing director of Mærsk Contractors Norway, Per Wulff, exchanged gifts and speeches in a ceremony in the control room on board the platform.

From the drilling deck on Mærsk Inspirer.

(Photo: Colin Dobinson)

World's largest jackup

The development solution is based on the movable installation Mærsk Inspirer, the world's largest jackup platform. The solution gives greater flexibility, mobility and lower costs than a conventional platform.

The platform was towed out from Haugesund in May last year, and production came on stream on February 12. The goal is to achieve plateau production in 2008. The first cargo of 500,000 barrels of oil is scheduled to be shipped in mid-March. In the meantime, the oil is stored in the floating storage unit, Navion Saga, a converted shuttle tanker.

Short lifespan may be extended

The subcontracted model was chosen because of the field's relatively short lifespan, estimated to about five years and a recovery rate of 45 percent.

However, plans are already underway to extend the field's lifespan by exploring nearby resources in the project Volve Future Wells. Exploration and development are taking place in parallel at a fast tempo alongside drilling, startup and commissioning. Volve South and West will be investigated first using multilateral branches, after which Theta South will be explored. The Volve field was separated from the Sleipner field, and existing infrastructure is therefore close at hand.

Gas flaring will cease as soon as the compressors are running and all produced water will be reinjected into the reservoir for pressure support. In this way, Volve will also be at the forefront of environmentally-friendly operations.

(Photo: Colin Dobinson)

Eight wells in 2008

A total of eight wells will be drilled in 2008, and Gunnar Nakken, production director for marginal fields in Norway, points out that the projected lifespan to 2014 is based on calculations that have not been adjusted for recent increases in the price of oil. With a high oil price and good chances of new discoveries in the area, the possibilities of extending operations should be good, he believes.

Good cooperation

"We are greatly looking forward to a continued cooperation with Mærsk," says Gunnar Nakken. He believes that the good cooperation achieved so far provides the opportunity for learning from each other and exchanging experience on this type of field.

Environmentally-friendly operation

When the Volve field is fully on stream in the near future, there will be no discharges of hydrocarbons to sea or air. Produced water will be reinjected into the formation in order to increase oil recovery, and when the compressors start working next week, gas flaring will also cease. Volve will therefore be at the forefront of environmentally-friendly operations on the Norwegian continental shelf.