30 years of Gullfaks oil

Gullfaks was something of a final exam for Statoil – the first field where the company was both developer and operator. Since production started on 22 December 1986, 2.6 billion barrels of oil have passed the loading buoys.

"Gullfaks is a prime example of the best that this industry has achieved in Norway," says Gunnar Nakken, senior vice president for the operations west cluster.

He points out that Gullfaks also played a key role in Statoil's development as an operating company. The company learned a huge amount from the development of Statfjord and from the international companies that were involved on the Norwegian continental shelf in the pioneering days. The establishment of the operations organisation in Bergen was a strategic decision, in order to build a petroleum cluster here.

"Wise decisions, outstanding subsurface work, the use of new technology and good team work in the Norwegian petroleum cluster have more than tripled the expected field life and ensured enormous value creation from Gullfaks. After 30 years, we still believe in Gullfaks, which has seen major investments and undergone extensive upgrades in recent years," continues Nakken, who is also Statoil's site manager in Bergen.

The Gullfaks organisation is very proud of what it has achieved in the past 30 years. They are a very tight-knit team.

"This solidarity was palpable in the wake of the Turøy accident in the spring. We have faced many tough challenges in Gullfaks' history, but none as difficult as this tragic accident," concludes Nakken.

The Golden Block

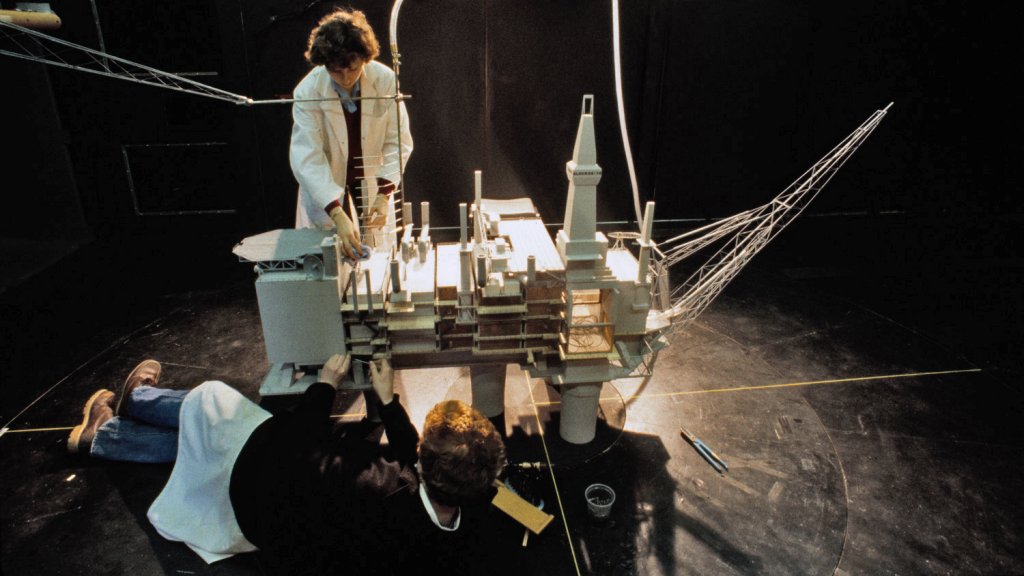

The name Gullfaks comes from "Gullblokken" (the Golden Block), as block 34/10 was known prior to its allocation in 1978. The Golden Block was awarded to a wholly Norwegian group consisting of Statoil (85%), Hydro (9%) and Saga (6%). This would be Statoil and the Norwegian petroleum industry's baptism by fire. Norwegian industry accounted for nearly 80% of the total investments.

The first explorations in the 1970s indicated that this was a significant oil and gas reservoir; however, at the time the field was expected to run out not long into the new millennium. Today, the production horizon stretches towards 2040.

30 years on the seabed

22 December is also the day Statoil opened the valves of its very first subsea well, in Gullfaks, marking the start of an incredible technological development. Statoil has been at the forefront of several of the most important breakthroughs in the subsea industry in the world. Without this technology, it would not have been possible to develop fields such as Åsgard and Troll Oil.

More satellites have subsequently been linked to Gullfaks: Gullfaks South has been developed with installations on the seabed and came on stream in October 1998, with production of oil and condensate and reinjection of associated gas. Phase two started in October 2001, comprising production and export of gas, linked to the A and C platforms.

The Rimfaks satellite, consisting of three subsea templates, has production pipes linked to Gullfaks A, while Skinfaks has a production system linked to the templates in Gullfaks South. Another example is Gimle, situated between Gullfaks and Visund, which is connected to Gullfaks C.

Reversed the decline

Gullfaks is also an outstanding example of improved oil recovery (IOR) and has won the Norwegian Petroleum Directorate's IOR prize, among other awards.

After a significant decline in production from Gullfaks in late 2010, production soon picked up again. In 2011 and 2012, wells with compromised integrity were repaired and the injection of water was stabilised. Water injection has been the main reason for the high recovery factor at Gullfaks. In addition, Statoil has developed subsea gas compression, in collaboration with others, which accelerates gas production.

The installation of new loading buoys in 2014 is another example of projects that are extending Gullfaks' lifetime, meaning the field is now expected to continue creating value for companies and society up until 2040.