Norwegian petroleum and energy minister Ola Borten Moe (left) presented the award to Statoil Åsgard subsea gas compression project manager Torstein Vinterstø and Aker Solutions subsea processing head Knut Nyborg (right).

The award was announced today, Wednesday, 29 August, in connection with ONS 2012 in Stavanger.

Åsgard subsea gas compression is one of Statoil's most demanding technology projects aimed at improved recovery.

Technology director Siri Espedal Kindem. (Photo: Harald Pettersen)

"We are pleased and proud to win this prize. With this technology in place, we can achieve significant improvement in both recovery rates and lifetimes for several gas fields. From Mikkel and Midgard on the Åsgard field, recovery is increased by 280 million barrels of oil equivalents," says technology director Siri Espedal Kindem.

Technological leap

Subsea processing, particularly gas compression, is an important technology for developing fields in deep water in vulnerable areas. Åsgard subsea gas compression brings us one step closer to realising our goal of a subsea factory.

A subsea factory is a processing facility on the seabed, which makes it possible to remotely control transport of hydrocarbons.

Ensures high gas stream

Åsgard subsea gas compression will contribute to maintaining the production level for the Midgard and Mikkel gas reservoirs on the Åsgard field.

The two reservoirs are developed with seabed installations, and the wellstream is sent in a joint pipeline to the Åsgard B platform, 50 and 70 kilometres away, respectively.

Analyses indicate that, towards the end of 2015, pressure in the reservoirs will be too low to avoid unstable flow and maintain a high production profile to Åsgard B. Compression provides the necessary force to ensure a high gas stream and recovery rate.

Energy-efficient

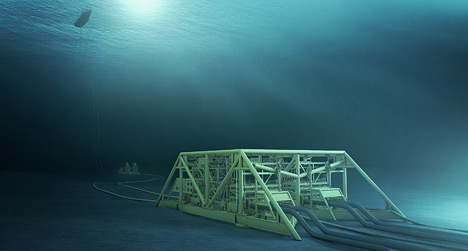

A large seabed structure with two compressors, pumps, scrubbers and coolers will be placed on the seabed, near the Midgard wellheads.

On Åsgard, dry gas compressors will be used. Gas and liquids will be separated before the gas is compressed. Afterwards, gas-liquid and gas will be blended in the same pipeline prior to transport to Åsgard B.

"The closer compression takes place to the well, the higher the effect and production rate. Performing compression on the seabed also gives us advantages in the form of better energy efficiency," explains Espedal Kindem.

Illustration: Åsgard subsea gas compression. (Illustration: Aker Solutions)