The drilling equipment on Gullfaks A must be reinforced several times in order to complete the record-long and almost horizontal well Gulltopp.

Tuesday 8 April was a red-letter day on the Gullfaks A platform in the North Sea. The most complicated well in StatoilHydro's history was successfully completed and hydrocarbons were flowing up through the well at 9910 metres. This is thus the longest producing well in the world drilled from an offshore platform.

Arne Sigve Nylund (Photo: Kim Laland)

"This is a day of rejoicing both for Gullfaks and StatoilHydro. We were aware of the risk that Gulltopp drilling from the platform might fail. This makes it extra great that we today have successfully completed the company's most demanding drilling operation," says Arne Sigve Nylund, the head of Operations West in StatoilHydro.

The experience gained by StatoilHydro is very valuable to the further development of both remote prospects at Gullfaks and on other fields in the company's portfolio.

"The increased range that we now envisage for platform drilling opens up new perspectives for effective exploitation of existing infrastructure, and thus increased producing life," Nylund says.

| Why drill such a long well? The record-long Gulltopp well is a result of the distance from the nearest platform. It is 10 kilometres from Gullfaks to the oil discovery. The alternative to drilling this distance would be to locate a subsea template on the seabed. This, however, would be far more expensive than drilling from an existing platform. The challenges underway made Gulltopp considerably more expensive than initially assumed. But experience from the project is very valuable and will now be used for developing similar oil finds at a lower cost. StatoilHydro may thus save billions using this solution. |

An extensive plan for how to extend the life of the field, which came on stream back in 1986, has been developed.

Demanding job

The drilling of Gulltopp has been a very demanding job that requires a go-ahead spirit, as well as innovation and perseverance.

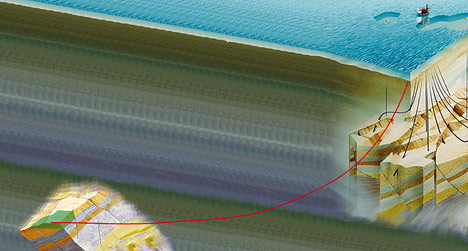

The 10-kilometre drill pipe was controlled from the drilling rig at the sea surface. It was run 150 metres down to the seabed, and then kilometre after kilometre through various types of rock strata.

The longer the drill pipe is, the more difficult it is to control the forces that are transferred to the drill bit down in the deep, thousands of metres away. This requires great attention and skills by personnel in charge of drilling.

"The Gulltopp well has been a great technological challenge, and was possible thanks to high professional skills among our own drilling and well personnel, in addition to crucial contribution by the involved suppliers," says Geir Slora, head of drilling and wells in StatoilHydro.

During traditional installation of casings the casing is filled with drilling mud and rubs against the well floor.

"There have been project delays due to subsurface conditions and demanding technical and operational challenges related to the well, brake system in the drilling rig and platform's power supply. It has therefore been necessary to upgrade the brake system and power supply," Slora says.

Successful filling of air into the casing

The working conditions below the seabed are always challenging. The conditions are unstable, with varying pressure and mixture of rocks.

For Gulltopp the conditions were even worse. This is an exceptionally shallow oil deposit. For each metre to be drilled down, it was necessary to drill four metres horizontally. Most height meters must be used at the top of the well.

In order to reduce the friction for Gulltopp the casing was instead filled with air. This makes the casing lighter, allowing it to be lifted from the bore hole floor. (Drawings: Jan Ulriksen)

When the well was drilled far enough into the seabed to be slanted, it must be drilled almost horizontally in order to hit the target.

Most of the well has a downward inclination of just seven degrees.

This poses great challenges with regard to the increasing friction between the drill strings and rocks underway when the well is extended.

The platform equipment has been reinforced several times during this process. But in order to drive the drill forward in the slack incline the friction in the well must be reduced.

Pulling an eight-kilometre casing that rubs against the bottom of the slack well was not possible. The drilling management decided to fill the casing with air. The casing would then hover in the hole rather than lying along the seabed. This was the key to success.

Facts about Gulltopp:

|