This piece of pipe marks Polarled’s crossing of the Arctic Circle. It was laid down on the seabed at 05:04 Friday morning, 21 August. In the foreground from the left: Johannes C. Irgens, Statoil vessel representative, Keith Hassage, Allseas superintendent, Sijmen van der Plicht, Allseas vessel master. (Photo: Lars Chr. Henrichsen, Statoil)

The 482-kilometre long and 36-inch wide pipeline will run from Nyhamna in western Norway to the Aasta Hansteen field in the Norwegian Sea. The world’s largest pipelaying vessel, Solitaire from Allseas, is carrying out the job and is advancing slowly, exactly 24.4 metres at a time, every sixth minute or so, around the clock.

Good progress

During the start-up in March the pipeline was pulled in to Nyhamna. During September the vessel will arrive at the Aasta Hansteen field, if weather permits. Even early in the autumn high waves and strong wind leading to interruptions must be expected. The weather has been good for a long period now:

«We are progressing well at the moment, conditions have been good for more than 50 days in a row, and at the end of July we set a record of laying 4.8 kilometres of pipes in one day,” says Kenneth Aksel Kristensen, one of Statoil’s company representatives on board the vessel.

Being from northern Norway he is particularly proud of helping lay the very first pipeline across the Arctic Circle. Polarled will also be the deepest pipeline on the Norwegian continental shelf – by the Aasta Hansteen field the water depth is 1260 metres. Furthermore, it will be the first time a 36-inch wide pipe is laid in such deep waters anywhere in the world.

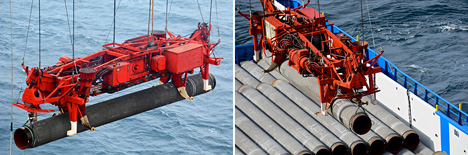

Pipe with this diameter has never before been laid this deep. Polarled will also be the deepest pipeline on the Norwegian continental shelf. (Photo: Eva Sleire)

Shuttle traffic

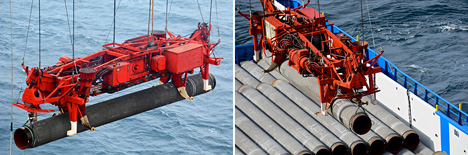

The vessel is a huge, well-oiled pipelaying machine which needs constant supply of pipes. Every pipe is 12.2 metres long and the vessel is laying around four kilometres of pipes a day. This means that it needs a supply of more than 300 pipes a day, filling two to three boats every day.

Two cranes are working hard like busy ants as they are lifting hundreds of pipes on board the vessel. One by one the 12-15-tonne heavy pipes are lifted on board – and when one boat is empty it only takes a few hours before the next boat arrives with more pipes. There are six boats in shuttle traffic transporting pipes.

«The pipes arrive from Wasco in the city of Mo i Rana, where they are coated. This means that they have been given a concrete layer to protect them from trawling and make them heavier,” explains Kristensen.

Assembly line

When a pipe is lifted on board the Solitaire it enters a huge assembly line. The pipe is sent from station to station through the factory of the 397-metre long and 41-metre wide vessel, where specialised operators perform their tasks. They are welding, checking, welding some more and checking some more before the welded joints are protected and the pipe becomes part of the long tail behind the Solitaire.

The pipeline is not laid in a straight line:

“We have examined the seabed thoroughly in advance to find the best route and also to avoid corals and large rocks,” says Arne Fosse, Statoil’s head of the Polarled construction work.

It takes six boat in shuttle traffic to keep the two cranes on Solitaire supplied with pipe around the clock. (Photo: Eva Sleire

Saving money

In his office in Stavanger project manager Alfred Øijord has reason to smile. After some periods of bad weather right after the pull-in to Nyhamna in March, the project is progressing well – also financially.

«We are currently expecting to deliver way below budget,» he says. “The original investment budget for the pipeline project was NOK 11.1 billion. We are now expecting an investment level of around NOK 7.5 billion, due to good planning, good market knowledge and good execution. We have also had favourable market conditions with regard to capacity and price.”

Building for the future

At start-up the gas from Aasta Hansteen will be the only gas passing through Polarled, but the pipeline has a diameter of 36 inches and capacity for more gas:

“We have therefore installed six connection points, call it future slip roads to the new gas highway,” says Håkon Ivarjord, Statoil’s project venture manager for the Polarled development project. “Polarled will open up for gas export to Europe from a completely new gas province, and with the infrastructure in place it will also be more attractive to explore the surrounding area.”

The pipelaying vessel Solitaire’s pipeline tail grows fast – with as much as five kilometers per day. (Photo: Eva Sleire)

24-hour operation

The Solitaire crew is working around the clock. It takes around 90 minutes from a pipe is lifted on board and enters production until it has become part of the ever-extending Polarled pipeline. There are 410 people on board the vessel, including two asset owner representatives from Statoil and eight people from DNV GL – who are also part of the day and night operation.

In a control room aft Max Misund is busy studying his computer screen – around every sixth minute he receives the result of the automatic ultrasound inspection made inside the vessel. Also this weld is approved.

The welding quality is good, he says:

“We have now checked more than 14,000 welds and the repair rate is 0.6%. That is an excellent result!»

The pipelaying work had to wait on weather for a couple of days, and gave the crew a welcome break.

“Laying several hundred kilometres almost without weather interruptions is very unusual. It is good to have a break to perform necessary maintenance on the pipelaying equipment, and not least to give the crew a welcome break before completing the pipelaying in 1260 metres of water,” concludes Arne Fosse.

This autumn the new highway for gas from the Norwegian Sea will be ready for use – on time and well below budget.