Local ripple effects

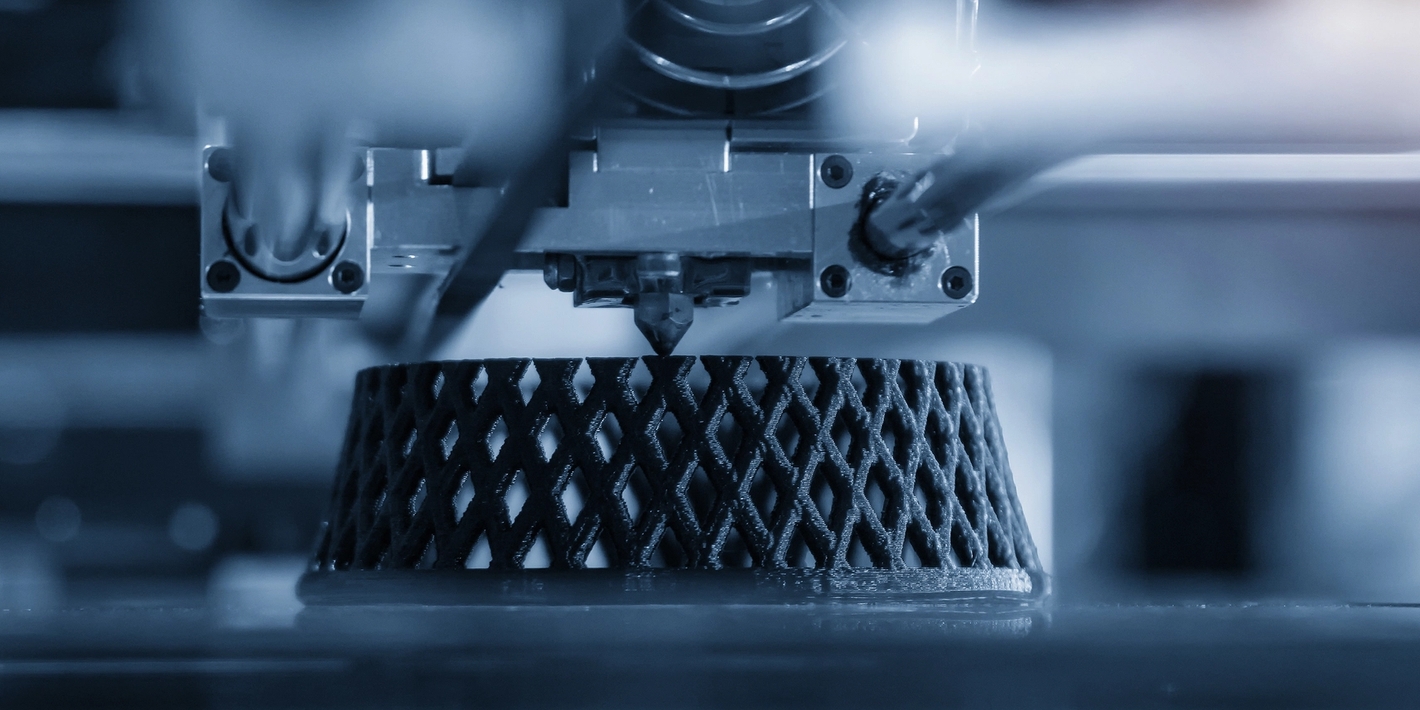

3D printing enables us to create ripple effects in the local communities where we operate, creating value locally through so-called «homesourcing». Most of the 3D printed parts which have been put in service in Norway have been produced by a supplier in Norway. Equinor is actively supporting the establishment of 3D printing hubs in northern Norway.

With the technology, we can download a design from anywhere in the world – be it at our locations in Brazil, northern Norway, or Canada – and produce it locally with 3D printing. It is efficient for us, and it contributes to communities by creating local jobs.

Case example 1: World record in the industry

At the Norne field, we produced the largest steel and metal object in our industry by 3D -printing. Ship needed to be replaced as part of the maintenance program. To ensure correct functionality the flange had to be changed at the same time. The lead time of a traditional flange was 40 weeks, the 3D printed, 3m in diameter flange took 10 weeks to produce – in Norway. This was made possible due to the collaboration between Equinor, Welmax, DNV and Kongsberg Maritime.

Case example 2: Increased demand for new service functions

With new technology and improved processes, there will be a need for jobs within new and different types of service functions.

3D printing has opened opportunities for welding robots. With this comes an increased demand for service functions such as robot programming, obtaining robots, welding technology, and then executing this work out in the field.

Case example 3: New hubs equals new jobs

Let’s take our work in Norway to exemplify further. To bring this to life locally, we need hubs that can produce the necessary parts locally when ordered. Hubs will be needed in Hammerfest, on the Helgeland coast, in Bergen and in other locations close to our supply bases. With this, there will be new jobs and new value creation that we do not have today.